Hotshot trailers are specialized trailers designed for use in the hotshot trucking industry, which involves the transportation of smaller, time-sensitive, and urgent cargo.

These trailers are typically smaller in size than traditional semi-trailers and can be attached to a one-ton truck or similar vehicle. Hotshot trailers come in different types and sizes, such as flatbeds, goosenecks, lowboys, step-decks, and dry van trailers.

Looking for a versatile and reliable trailer for your hot shot trucking needs?

Learn all about hot shot trailers, including their sizes, capacities, features, and deck options.

Discover the jacks, equipment, and suspension features that make hot shot trailers ideal for hauling heavy and oversized loads. Whether you’re transporting equipment, vehicles, or other cargo, a hot shot trailer can help you get the job done safely and efficiently.

Table of Contents

Types of Hot Shot Trailers

There are different types of hot shot trailers that are designed to transport a wide range of cargo, including heavy equipment, vehicles, and other goods. Here are the main types of hot shot trailers:

Flatbed Trailers

Flatbed trailers can haul all kinds of loads but require more skill to protect the cargo.

Flatbed trailers are the most common type of hot shot trailers. Also, it is a part of flatbed shipping. They have a flat deck with no sides or roof, allowing for easy loading and unloading of cargo. Flatbed trailers come in various sizes and weight capacities and are ideal for carrying large or irregularly-shaped cargo that cannot fit in a standard enclosed trailer.

Gooseneck Trailers

Gooseneck trailers have a hitch that attaches to a ball on the bed of a pickup truck. This design allows for better weight distribution, improved stability, and increased maneuverability compared to bumper-pull trailers.

Such trailers come in various sizes and weight capacities and are suitable for hauling large, heavy equipment and vehicles. Depending on the trucking type it becomes larger to shorter. You may have a look to understand one of the variants of it- PJ trailers reviews

Ideally, a 40 ft gooseneck trailer is the best choice. But, in reality, you can even go for the ones up to 45 ft long.

Gooseneck trailers can carry heavier loads of up to 15,000 pounds. They are ideal for transporting large equipment and machinery.

Bumper Pull Trailers

It is attached to the bumper or frame of a tow vehicle using a ball hitch. People also know them as tag-along trailers, drag trailers, or conventional trailers. They are typically smaller and lighter than gooseneck trailers.

Lowboy Trailers

Lowboy trailers are designed to transport heavy and oversized cargo, such as construction equipment, bulldozers, and excavators. They have a low center of gravity, which makes them more stable when transporting tall loads.

Lowboy trailers have a hydraulic or mechanical detachable neck that allows for easy loading and unloading of cargo.

They have a low deck height and are often fitted with ramps for easy loading and unloading.

Dovetail Shipping Trailers

They are flatbed trailers that have a sloped rear section that allows for easier loading and unloading of cargo.

Known as beavertail trailers, ramp trailers, or drop deck trailers, they have foldable or detachable ramps that can be lowered to the ground to create a smooth transition from the trailer deck to the road surface.

Step-Deck Trailers

Hot shot Step-deck trailers are similar to flatbed trailers but have two different deck heights. The upper deck is shorter than the lower deck, allowing for the transportation of taller cargo while maintaining a lower center of gravity.

Also known as drop deck trailers, single drop trailers, or lowboy trailers, these have a higher deck in the front section that is attached to the fifth wheel of the truck, and a lower deck in the rear section.

Step deck trailers consist of two levels. They have a lower deck at the front and a raised deck at the rear.

This design allows them to carry taller cargo without the need for permits for oversized loads.

Step deck trailers can carry loads of up to 20,000 pounds.

Even they are ideal for transporting items. Such as heavy machinery, construction materials, and oversized cargo.

Step-deck trailers are suitable for carrying tall cargo such as heavy machinery, vehicles, and other oversized equipment.

Dry Van Trailers

Dry van trailers are enclosed trailers that provide protection from weather and theft. They come in various sizes and weight capacities and are suitable for transporting goods that require protection from the elements, such as furniture, electronics, and other sensitive cargo. Dry van trailers are great for Power only trucking services

Drop Deck Trailers

Drop deck trailers are equal to step deck trailers. But they have a lower deck height at the rear.

This design allows for increased height clearance for taller items while maintaining a low deck height for easy loading and unloading.

Anyway, hot shot trucking requires specialized equipment that can handle smaller, time-sensitive loads over shorter distances.

The above trailers offer a variety of features and benefits that cater to specific needs. Such as increased weight capacity, protection from the elements, or specialized loading and unloading capabilities.

Enclosed Trailers

Enclosed trailers are another popular option for hotshot trucking. These trailers are fully enclosed and offer protection from the elements.

These features make them ideal for trucking fragile or sensitive items for medical device logistics. They are also commonly used for hauling high-value items such as electronics or artwork.

What is rgn trailers?

An RGN (Removable Gooseneck) trailer is a type of flatbed trailer used for transporting heavy and oversized equipment or machinery. RGN trailers have a detachable front end, which allows the trailer to be lowered to the ground for loading and unloading. This feature makes RGN trailers ideal for hauling equipment that is taller than a standard flatbed trailer or requires a lower loading height.

RGN trailers are commonly used in industries such as construction, mining, and agriculture, where oversized or heavy equipment needs to be transported to job sites or between locations.

They can handle a wide variety of equipment and machinery, including bulldozers, excavators, and cranes, making them a versatile option for heavy equipment hauling.

RGN trailers typically have three axles and are designed to distribute the weight of the cargo evenly across the trailer. The detachable gooseneck allows the trailer to be disconnected from the truck and the cargo to be driven or rolled onto the trailer. Once the cargo is secured, the gooseneck is reattached and the trailer is ready to be transported.

What size trailer is best for hotshot trucking?

The best-size trailer for hotshot trucking depends on the type and amount of freight being transported.

Generally, hot shot trucking involves transporting smaller and time-sensitive loads. So a smaller trailer is often preferred for its flexibility and movement.

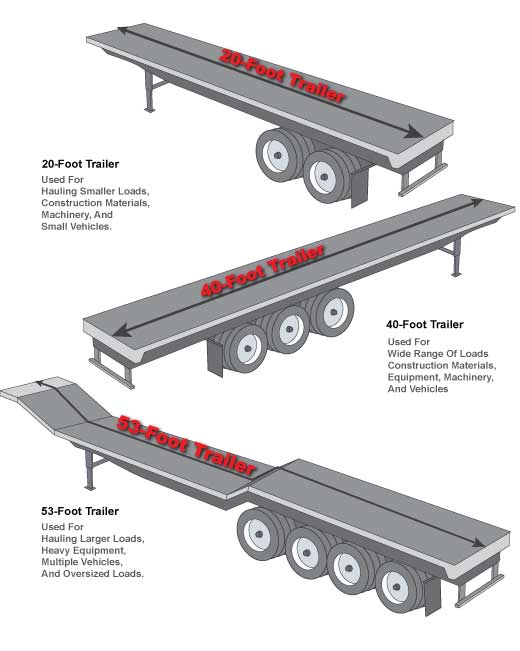

The most commonly used trailer size for hot shot trucking is a 40-foot flatbed trailer.

However, some hot shot truckers may also use smaller trailers, such as 20-foot or 30-foot flatbed trailers, depending on the size and weight of the load.

Yet, the trailer size and weight can vary by state and region. So you need to research and comply with all applicable laws and regulations.

You can read another article on what size trailer is best for hot shot trucking to get detailed insights!

Sizes and Capacities

Hot shot trailers come in various sizes and weight capacities, depending on the specific needs of the cargo being transported. Here are some of the key factors to consider when selecting the appropriate hot shot trailer size and capacity:

Length and Width

The size of the trailer determines the amount of cargo that can be transported. The length and width of hot shot trailers vary, with most trailers ranging from 20 to 40 feet in length and 6 to 8.5 feet in width.

Weight Capacities

Weight capacity is another important factor to consider when selecting a hot shot trailer. The weight capacity of hot shot trailers can range from 3,000 to 30,000 pounds, with most trailers having a capacity between 10,000 and 14,000 pounds.

It is important to note that weight capacities can vary based on the type of trailer and the number of axles.

Load Securement Features

Hot shot trailers come equipped with various load securement features, such as

- tie-downs

- chains

- straps

- Winches

To keep the cargo in place during transport. The load securement features should be strong enough to keep the cargo in place and prevent it from shifting during transit.

You will get to know more about from our post equipment needed for hotshot trucking

Equip your truck and trailer with the necessary accessories and tools for hotshot trucking

Essential items include a spare tire kit, a jack stand, a tire pressure gauge, a fire extinguisher, an emergency kit, tie-down straps or chains, tarps, or covers for cargo protection.

You will also need to invest in a dashcam, an ELD device or app for logging hours of service, or a CB radio for communication with other dri

Braking features

Hot shot trailers come with various braking features that are designed to help the driver slow down or stop the trailer in case of an emergency. Here are some of the common braking features found in hot shot trailers:

Electric Brakes

Electric brakes are the most common type of braking system found in 10 to 15 tons hot shot trailers.

They are activated when the driver applies the brakes in the towing vehicle, sending an electric signal to the brakes on the trailer.

Electric brakes are effective in stopping the trailer and are easy to maintain.

Measurement type: used for trucks which is 10 to 15 tons in weight

Hydraulic Surge Brakes

Hydraulic surge brakes use a hydraulic system to activate the brakes on the trailer when the towing vehicle slows down or stops. This type of braking system is commonly found in smaller hot shot trailers and can be effective in stopping the trailer, but requires more maintenance than electric brakes.

Measurement type: 7k to 12k axles

Air Brakes

Air brakes are a more sophisticated type of braking system that uses compressed air to activate the trailer brakes. They are commonly found in larger hot shot trailers and can provide more stopping power than electric or hydraulic surge brakes. Air brakes are also more complex and require regular maintenance to ensure proper operation.

Measurement type: Air brakes are available on 10, 12k, & 16k, axles.

Anti-Lock Brakes

Anti-lock brakes (ABS) are a safety feature that prevents the trailer wheels from locking up when the driver applies the brakes. ABS is designed to help the driver maintain control of the trailer during sudden stops or emergency braking situations.

Suspension features

Hot shot trucks come with various suspension features that are designed to provide stability and support during transportation. Here are some common suspension features found in hot shot trucks:

Leaf Spring Suspension

Leaf spring suspension is a common type of suspension found in hot shot trucks.

It uses multiple layers of metal springs to absorb shocks and vibrations during transit. Leaf spring suspension is known for its durability and reliability, and is commonly found in heavier hot shot trucks.

Air Suspension

Air suspension uses air-filled bags to provide support and cushioning during transportation. It can be adjusted to accommodate different types of cargo and road conditions. It is great for providing a smoother ride than leaf spring suspension.

Coil Spring Suspension

Coil spring suspension uses metal coils to provide support and cushioning during transportation. It is commonly found in lighter hot shot trucks and can provide a smoother ride than leaf spring suspension.

Rubber Suspension

Rubber suspension uses rubber blocks or pads to provide support and cushioning during transportation. It is commonly found in lighter hot shot trucks and can provide a smooth ride, but may not be as durable as other types of suspension.

Shock Absorbers

Shock absorbers are a key component of hot shot truck suspension systems. They are designed to absorb shocks and vibrations during transit, and to minimize the effects of bumps and potholes in the road. Shock absorbers can be hydraulic or pneumatic, and are critical for ensuring a smooth and safe ride.

What are the jacks for hot shot trailers?

Hotshot trailers are equipped with jacks to assist with the loading and unloading of cargo. Here are some of the features and types of jacks commonly used on hot shot trailers:

- Manual jacks: Manual jacks are operated by hand and can be either scissor jacks or screw jacks. They are typically used on smaller trailers or as backup jacks on larger trailers.

- Hydraulic jacks: Hydraulic jacks use hydraulic fluid to lift and support the trailer during loading and unloading. They are typically used on larger trailers and can be either single or double acting.

- Electric jacks: Electric jacks use an electric motor to lift and lower the trailer. They are typically used on larger trailers and can be controlled with a remote.

- Drop-leg jacks: Drop-leg jacks are a type of manual or electric jack that have an additional section that can be dropped down to provide added support. They are commonly used on larger trailers or trailers that are loaded and unloaded frequently.

- Stabilizer jacks: Stabilizer jacks are designed to stabilize the trailer when it is parked or in use. They are typically mounted on the corners of the trailer and can be either manual or electric.

Toolbox and storage

Here are some common features of hot shot trailer toolboxes and storage:

Toolboxes

Toolboxes are a common feature in hot shot trailers, providing a secure and organized space for tools and equipment. Toolboxes can be mounted on the trailer tongue, on the side of the trailer, or at the rear of the trailer. They can be made of steel or aluminum and may have locking mechanisms to prevent theft.

Storage Compartments

Storage compartments are similar to toolboxes but are typically larger and can accommodate a wider range of equipment and supplies. Storage compartments can be mounted on the side of the trailer or at the rear and can be accessed through doors or hatches. They may also have locking mechanisms to provide security.

Tie-Downs

Tie-downs are essential for securing cargo during transportation, and hot shot trailers may come with built-in tie-down points. These can include D-rings, stake pockets, or E-track systems. Tie-downs should be positioned strategically to prevent cargo from shifting during transit.

Customization

Many hotshot trailer manufacturers offer customization options for toolboxes and storage compartments. This can include customized sizes and shapes, as well as interior shelving or dividers to help organize equipment and supplies.